Enhancing Performance: How Special Barrel Screws Revolutionize Extrusion Processes

Extrusion processes play a crucial role in various industries, such as plastics, rubber, and food manufacturing, where precise and efficient material shaping is required. One key component that significantly impacts extrusion performance is the barrel screw. This article delves into the world of special barrel screws and explores how they revolutionize extrusion processes, leading to improved productivity, enhanced product quality, and cost savings.

1. Understanding Special Barrel Screws:

- Defining special barrel screws and their significance in extrusion processes.

- Exploring the unique features and design characteristics of special barrel screws, including advanced flight geometry and mixing elements.

- Discussing the different types of special barrel screws available and their specific applications in various extrusion processes.

2. Enhancing Material Melting and Homogeneity:

- Examining how special barrel screws optimize the melting and homogenization of materials during extrusion.

- Discussing the importance of screw design, including channel depths, compression ratios, and screw pitch, in achieving efficient material melting.

- Exploring the role of special mixing elements, such as kneading blocks and mixing pins, in promoting thorough material blending and homogeneity.

3. Controlling Residence Time and Shear Rate:

- Highlighting the ability of special barrel screws to control residence time and shear rate, crucial factors in extrusion processes.

- Discussing the impact of residence time and shear on material properties, molecular weight distribution, and final product quality.

- Exploring how special barrel screws offer enhanced control and flexibility in adjusting residence time and shear rate to meet specific process requirements.

4. Handling High Viscosity and Specialty Materials:

- Showcasing the capability of special barrel screws to handle high viscosity and specialty materials in extrusion processes.

- Discussing the challenges associated with processing high-viscosity materials and how special barrel screws overcome them.

- Exploring case studies and success stories of industries that have benefited from special barrel screws when working with challenging materials, such as filled polymers or highly shear-sensitive substances.

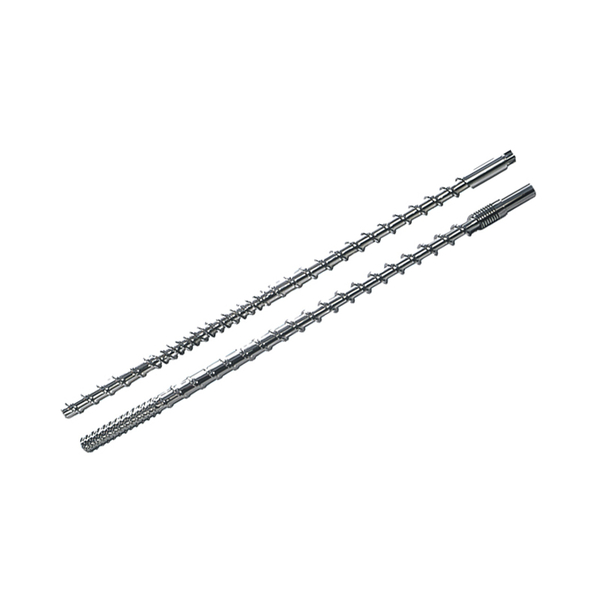

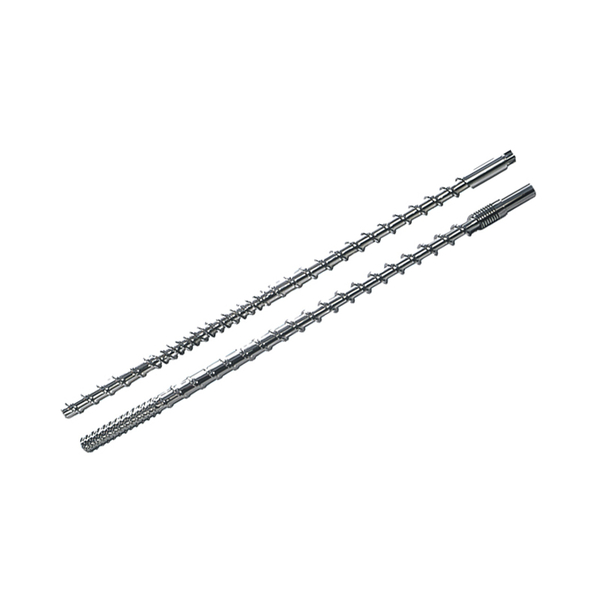

Mixing type extruder screw

It make melt more well-distributed, plastination better. It usually used to add fully expected, the second of

extrusion materials. Such as PE+CaCO2 out cotton spend stick etc..