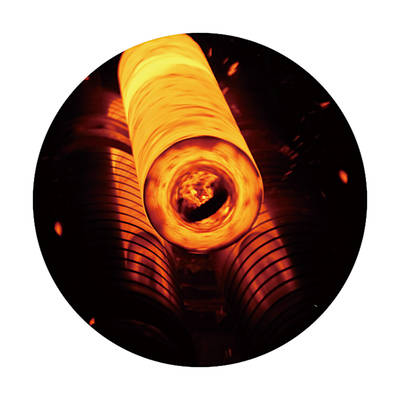

1. Evaluating Alloy Barrel Screw Suppliers: Benefits1) Enhanced Wear Resistance: The high-strength alloy coating on the surface of alloy barrel screws provides excellent wear resistance, making them ideal for applications where the screw encounters abrasive materials or experiences high levels of stress. This feature significantly extends the service life of the screw, reducing downtime for maintenance and replacements.

2) Improved Corrosion Resistance: Industrial environments often expose equipment to corrosive elements, which can compromise their performance and durability. Alloy barrel screws, with their protective alloy coating, exhibit exceptional corrosion resistance, ensuring prolonged service life even in harsh operating conditions. This resistance to corrosion minimizes the risk of equipment failure and associated production delays.

3) Superior Heat Resistance: Many industrial processes involve high temperatures that can degrade standard screws over time. Alloy barrel screws, with their steel core, offer superior heat resistance, enabling them to withstand elevated temperatures without compromising performance. This characteristic makes them invaluable in applications such as plastic extrusion, injection molding, and rubber processing, where high temperatures are prevalent.

1) The versatility of alloy barrel screws allows them to be applied in a wide range of industrial sectors, transforming processes and delivering significant benefits. Some notable applications include:

2) Plastic and Rubber Manufacturing: Alloy barrel screws play a crucial role in plastic extrusion, injection molding, and rubber processing. Their exceptional wear resistance and heat resistance enable consistent performance and extended service life, resulting in enhanced productivity, reduced downtime, and improved product quality.

3) Food and Beverage Processing: In the food and beverage industry, alloy barrel screws find utility in extrusion processes for producing snacks, cereals, and confectionery items. The screws' corrosion resistance and compliance with food-grade standards ensure product integrity and safety while facilitating efficient production.

4) Chemical and Pharmaceutical Industries: Alloy barrel screws are used in chemical and pharmaceutical manufacturing processes, where precision, durability, and resistance to corrosive materials are paramount. These screws enable efficient mixing, compounding, and extrusion of materials, enhancing productivity and ensuring the quality of end products.

English

English 中文简体

中文简体