Zhejiang Bimetal Machinery Co., Ltd. (formerly Zhejiang Zhoushan Dinghai Chen’s Machinery Co., Ltd.) is located at the coast of East China Sea, adjacent to the famous international deep-water port – Ningbo Beilun Port.

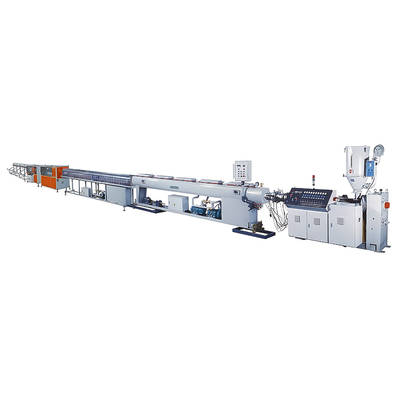

Bimetal is professional China Plastic PVC/PP/PE Pipe Extrusion Line Manufacturers and PVC PP PE Pipe Extrusion Line Suppliers which specializes in manufacturing series of screws, rubber melting cylinder products. Products are widely used in the 30-40000 grams injection molding machine, the 15-250mm single screw extruder, and the 30-130mm conical and parallel twin-screw extruder and all kinds of rubber machine, weaving machine, puffed food machine. All of the products are made of quality 38CrMoALA steel. By employment of fine processes of quenching and tempering, stiffening, nitriding, grinding, finishing, and guidance of ISO9002 International Quality Control System, products are in line with international standards. GⅡ 113 nickel-based alloy (latest 3# steel) screw cylinder is also one of our fist products; it is applicable for alloy bimetal (PTA) welding. In addition to providing balance equipment for complete machine companies abroad, we are also a leading Supplier undertaking OEM service, surveying and mapping assistance, as well as design services for big and small companies at home. No matter you are our existing partner or potential customer, with products and services, we warmly welcome your visit and inquiries with our wholeheartedly and thoughtful services. We also custom PVC PP PE Pipe Extrusion Line. We also wholesale in bulk.

English

English 中文简体

中文简体