Unlocking the Potential: Exploring the Advantages of Special Barrel Screws in Manufacturing

In the realm of manufacturing, specialized equipment plays a crucial role in optimizing production processes and achieving superior results. One such equipment that holds significant importance is the special barrel screw. This article aims to delve into the advantages of special barrel screws and how they unlock the potential for enhanced manufacturing across various industries.

1. Understanding Special Barrel Screws:

- Defining special barrel screws and their unique characteristics that set them apart from standard barrel screws.

- Exploring the different types of special barrel screws, including barrier screws, mixing screws, and vented screws.

- Discussing the importance of precision engineering and material selection in designing special barrel screws for specific manufacturing applications.

2. Enhanced Material Processing:

- Examining how special barrel screws improve material processing in manufacturing operations.

- Highlighting the benefits of barrier screws in ensuring efficient melt mixing and enhancing material homogeneity.

- Discussing the role of mixing screws in achieving thorough blending of materials with different viscosities, additives, or colorants.

3. Improved Product Quality:

- Exploring how special barrel screws contribute to the production of high-quality products.

- Discussing the impact of special barrel screws on reducing product defects, such as melt inconsistencies, air bubbles, or unmelted particles.

- Highlighting the importance of optimized screw design and processing parameters in achieving superior product quality.

4. Versatility and Customization:

- Showcasing the versatility of special barrel screws in accommodating a wide range of materials and applications.

- Discussing the ability to customize special barrel screws to meet specific manufacturing requirements, including size, geometry, and material compatibility.

- Exploring case studies and success stories of industries that have leveraged special barrel screws for improved production outcomes.

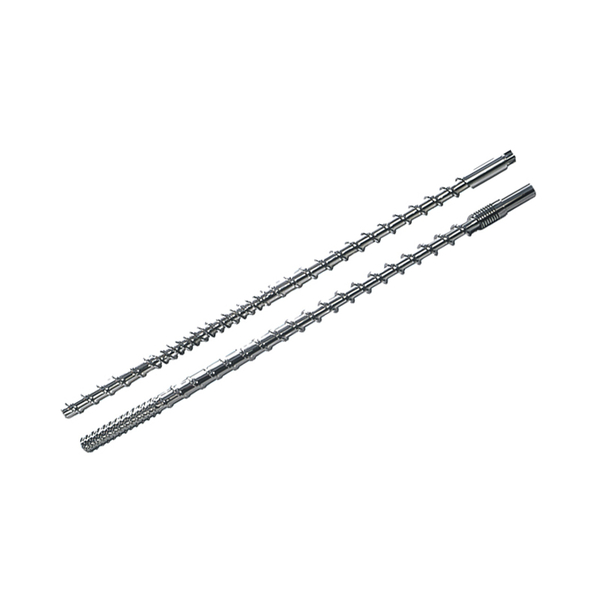

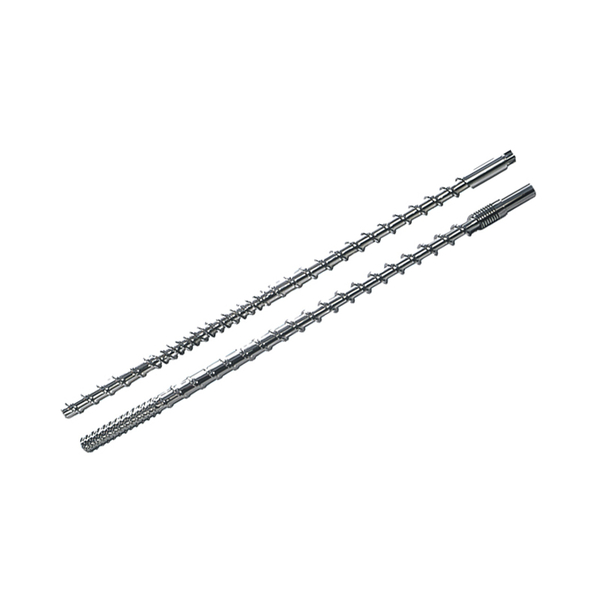

Mixing type extruder screw

It make melt more well-distributed, plastination better. It usually used to add fully expected, the second of

extrusion materials. Such as PE+CaCO2 out cotton spend stick etc..